Asked by Gloria Martin-Mays on Apr 24, 2024

Verified

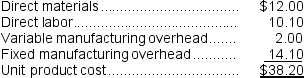

Foto Company makes 50,000 units per year of a part it uses in the products it manufactures.The unit product cost of this part is computed as follows:  An outside supplier has offered to sell the company all of these parts it needs for $37.30 a unit.If the company accepts this offer, the facilities now being used to make the part could be used to make more units of a product that is in high demand.The additional contribution margin on this other product would be $310,000 per year.

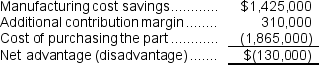

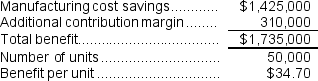

An outside supplier has offered to sell the company all of these parts it needs for $37.30 a unit.If the company accepts this offer, the facilities now being used to make the part could be used to make more units of a product that is in high demand.The additional contribution margin on this other product would be $310,000 per year.

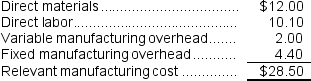

If the part were purchased from the outside supplier, all of the direct labor cost of the part would be avoided.However, $9.70 of the fixed manufacturing overhead cost being applied to the part would continue even if the part were purchased from the outside supplier.This fixed manufacturing overhead cost would be applied to the company's remaining products.

Required:

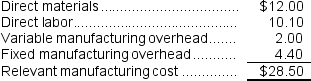

a.How much of the unit product cost of $38.20 is relevant in the decision of whether to make or buy the part?

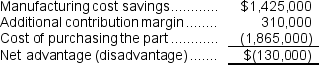

b.What is the financial advantage (disadvantage)of purchasing the part rather than making it?

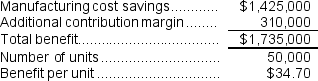

c.What is the maximum amount the company should be willing to pay an outside supplier per unit for the part if the supplier commits to supplying all 50,000 units required each year?

Make or Buy

A decision-making process regarding whether to produce goods in-house or purchase them from an external supplier.

Fixed Manufacturing Overhead

Indirect manufacturing costs that remain constant regardless of the level of production, such as factory rent and salaries of supervisory staff.

Direct Labor Cost

A rephrased definition: The cost incurred from the labor of workers who actively contribute to the manufacturing or creation of a product.

- Comprehend the idea of outsourcing and decisions related to make-or-buy.

- Evaluate financial advantages and disadvantages in various decision-making scenarios.

Verified Answer

SW

shikoh wangariMay 02, 2024

Final Answer :

a.Relevant cost per unit:  b.Net advantage (disadvantage):

b.Net advantage (disadvantage):  c.Maximum acceptable purchase price:

c.Maximum acceptable purchase price:

b.Net advantage (disadvantage):

b.Net advantage (disadvantage):  c.Maximum acceptable purchase price:

c.Maximum acceptable purchase price:

Learning Objectives

- Comprehend the idea of outsourcing and decisions related to make-or-buy.

- Evaluate financial advantages and disadvantages in various decision-making scenarios.