Asked by matthew guardanapo on Apr 29, 2024

Verified

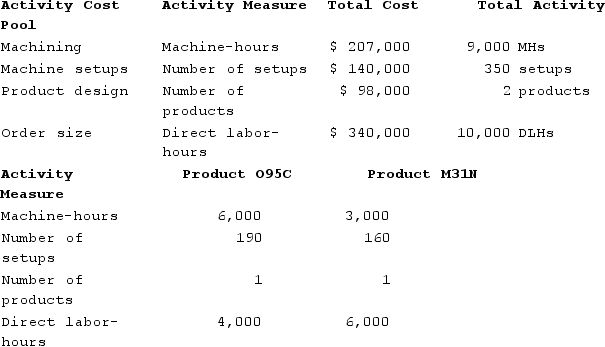

Fletes Corporation manufactures two products: Product O95C and Product M31N. The company uses a plantwide overhead rate based on direct labor-hours. It is considering implementing an activity-based costing (ABC) system that allocates its manufacturing overhead to four cost pools. The following additional information is available for the company as a whole and for Products O95C and M31N.  Using the ABC system, how much total manufacturing overhead cost would be assigned to Product O95C?

Using the ABC system, how much total manufacturing overhead cost would be assigned to Product O95C?

A) $392,500

B) $136,000

C) $399,000

D) $263,000

Product O95C

A specific product, potentially a model or version identifier, although the exact nature depends on the context.

- Understand the principles of activity-based costing (ABC) and how it allocates manufacturing overhead to products.

- Determine the fraction of aggregate overhead charges attributed to particular products based on Activity-Based Costing (ABC) information.

Verified Answer

ZK

Zybrea KnightMay 04, 2024

Final Answer :

C

Explanation :

To calculate the manufacturing overhead cost assigned to Product O95C using the ABC system, we need to multiply the cost driver rates (based on cost pools) by the activity levels of each cost driver used by Product O95C.

The cost pools and cost driver rates for the ABC system are as follows:

- Machining: $25 per machine-hour

- Setup: $32 per setup hour

- Materials handling: $16 per material move

- Inspection: $41 per inspection hour

Using the information provided, we can calculate the activity levels of each cost driver used by Product O95C:

- Machining: 8,000 machine-hours

- Setup: 500 setup hours

- Materials handling: 2,000 material moves

- Inspection: 1,500 inspection hours

Now we can multiply the activity levels by the respective cost driver rates and add up the total costs:

- Machining: 8,000 x $25 = $200,000

- Setup: 500 x $32 = $16,000

- Materials handling: 2,000 x $16 = $32,000

- Inspection: 1,500 x $41 = $61,500

Total manufacturing overhead cost assigned to Product O95C using the ABC system: $200,000 + $16,000 + $32,000 + $61,500 = $309,500

Therefore, the best choice is C: $399,000.

The cost pools and cost driver rates for the ABC system are as follows:

- Machining: $25 per machine-hour

- Setup: $32 per setup hour

- Materials handling: $16 per material move

- Inspection: $41 per inspection hour

Using the information provided, we can calculate the activity levels of each cost driver used by Product O95C:

- Machining: 8,000 machine-hours

- Setup: 500 setup hours

- Materials handling: 2,000 material moves

- Inspection: 1,500 inspection hours

Now we can multiply the activity levels by the respective cost driver rates and add up the total costs:

- Machining: 8,000 x $25 = $200,000

- Setup: 500 x $32 = $16,000

- Materials handling: 2,000 x $16 = $32,000

- Inspection: 1,500 x $41 = $61,500

Total manufacturing overhead cost assigned to Product O95C using the ABC system: $200,000 + $16,000 + $32,000 + $61,500 = $309,500

Therefore, the best choice is C: $399,000.

Learning Objectives

- Understand the principles of activity-based costing (ABC) and how it allocates manufacturing overhead to products.

- Determine the fraction of aggregate overhead charges attributed to particular products based on Activity-Based Costing (ABC) information.