Asked by Sasha Munir on Jun 01, 2024

Verified

A work cell is required to make 140 computerized diagnostic assemblies (for installation into hybrid automobiles) each day. The cell currently works an eight hour shift, of which seven hours is available for productive work. These assemblies require five operations. Standard times for these operations are: Operation A, 3.0 minutes, B, 1.8 minutes, C, 2.4 minutes, D, 2.5 minutes, and E, 1.4 minutes. What is takt time for this cell? How many workers will be needed to achieve this schedule? Use the grid below to construct a work balance chart for this cell.

Computerized Diagnostic

The use of computer systems and software to identify defects or problems in machinery or electronic devices.

Standard Times

Set durations established for completing specific tasks, often used in manufacturing and labor planning.

Hybrid Automobiles

Vehicles that use a combination of at least one electric motor alongside an internal combustion engine to propel the vehicle.

- Apprehend the theory of takt time and its implementation in the enhancement of production productivity.

- Employ ranking of tasks and assignment delegation to ensure balanced operations in assembly lines.

Verified Answer

ZK

Zybrea KnightJun 01, 2024

Final Answer :

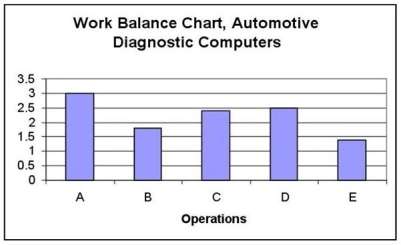

Takt time = 420 / 140 = 3 minutes/unit. Total operation time = 3.0 + 1.8 + 2.4 + 2.5 + 1.4 = 11.1 minutes. A minimum of four workers are required (11.1 / 3 = 3.7), but to balance at 3 min./unit requires five. The balance chart appears below.

Learning Objectives

- Apprehend the theory of takt time and its implementation in the enhancement of production productivity.

- Employ ranking of tasks and assignment delegation to ensure balanced operations in assembly lines.