Asked by Norma Ocampo on Jul 20, 2024

Verified

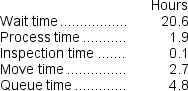

Simkin Corporation keeps careful track of the time required to fill orders.Data concerning a particular order appear below:  The manufacturing cycle efficiency (MCE) was closest to:

The manufacturing cycle efficiency (MCE) was closest to:

A) 0.46

B) 0.06

C) 0.20

D) 0.19

Manufacturing Cycle Efficiency (MCE)

Process (value-added) time as a percentage of throughput time.

- Understand and apply the concept of manufacturing cycle efficiency (MCE).

Verified Answer

YA

Youssef Al MakdissiJul 23, 2024

Final Answer :

C

Explanation :

In order to calculate the MCE, we need to divide the value-added time by the total manufacturing time.

Value-added time = Time spent actually working on the product

Total manufacturing time = Total time from start to finish of the order

From the data given, we can calculate the value-added time to be 4.7 hours (the sum of the times for cutting, welding, and painting).

The total manufacturing time is 23.5 hours (the sum of all the times given).

Therefore, MCE = 4.7/23.5 = 0.20 (rounded to two decimal places).

Thus, the closest choice to the calculated MCE is C (0.20).

Value-added time = Time spent actually working on the product

Total manufacturing time = Total time from start to finish of the order

From the data given, we can calculate the value-added time to be 4.7 hours (the sum of the times for cutting, welding, and painting).

The total manufacturing time is 23.5 hours (the sum of all the times given).

Therefore, MCE = 4.7/23.5 = 0.20 (rounded to two decimal places).

Thus, the closest choice to the calculated MCE is C (0.20).

Explanation :

Throughput time = Process time + Inspection time + Move time + Queue time

= 1.9 hours + 0.1 hours + 2.7 hours + 4.8 hours = 9.5 hours

MCE = Value-added time (Process time)÷ Throughput (manufacturing cycle)time

= 1.9 hours ÷ 9.5 hours = 0.20

= 1.9 hours + 0.1 hours + 2.7 hours + 4.8 hours = 9.5 hours

MCE = Value-added time (Process time)÷ Throughput (manufacturing cycle)time

= 1.9 hours ÷ 9.5 hours = 0.20

Learning Objectives

- Understand and apply the concept of manufacturing cycle efficiency (MCE).