Asked by Mckenna Grimm on May 06, 2024

Verified

Bob Dresser operates a major appliance warranty service centre. His operation has two check stations that are required at the end of every repair task performed by his appliance repair staff. These are the Functionality Review (FR) and the Overall Scan (OS). The FR must be performed successfully before the OS is begun. On Friday morning, six repair jobs are completed, awaiting these two inspection activities. Processing times are given in minutes.

Job FR OS A 5030 B 3555 C 2520 D 2035 E 1510 F 1025\begin{array} { | c | c | c | } \hline \text { Job } & \text { FR } & \text { OS } \\\hline \text { A } & 50 & 30 \\\hline \text { B } & 35 & 55 \\\hline \text { C } & 25 & 20 \\\hline \text { D } & 20 & 35 \\\hline \text { E } & 15 & 10 \\\hline \text { F } & 10 & 25 \\\hline\end{array} Job A B C D E F FR 503525201510 OS 305520351025 a. What is the optimal sequence of jobs for the objective of minimizing the total flow time?

b. Show your work, and document the sequence.

c. Chart the solution to this problem.

d. What jobs are being processed at time period 90?

e. What is the total flow time of this problem?

FROS20406080100120140160180200\begin{array} { | l | l | l | l | l | l | l | l | l | l | l | } \hline \mathrm { FR } & & & & & & & & & & \\\hline \mathrm { OS } & & & & & & & & & & \\\hline & 20 & 40 & 60 & 80 & 100 & 120 & 140 & 160 & 180 & 200 \\\hline\end{array}FROS20406080100120140160180200

Functionality Review

An evaluation process to ensure a product, system, or process meets necessary functionality requirements and specifications.

Major Appliance

Large electrical or gas appliances used in the home, such as refrigerators or washing machines, designed for routine housekeeping tasks.

Overall Scan

A comprehensive review or assessment of a system, plan, or situation to understand its overall condition or effectiveness.

- Apply Johnson's rule to find the optimal job sequence for minimizing makespan in a two-machine system.

- Review the capability of different scheduling systems considering criteria such as average flow time, work-in-process, lateness, and makespan.

Verified Answer

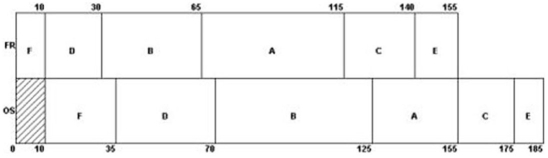

(b) Supporting work appears in the table below. FR OS Order Done 1 Done 2 (flow time) A 50.30. fourth 115.155.B35.55. third 65.125.C25.20. fifth 140.175.D20.35. second 30.70.E15.10. sixth 155.185. F 10.25. first 10.35. Makespan 185.\begin{array}{|r|r|r|r|r|r|}\hline & \text { FR } & \text { OS } & \text { Order } & \text { Done 1 } & \begin{array}{r}\text { Done 2 } \\\text { (flow time) }\end{array} \\\hline \text { A } & 50 . & 30 . & \text { fourth } & 115 . & 155 . \\\hline \mathbf{B} & 35 . & 55 . & \text { third } & 65 . & 125 . \\\hline \mathrm{C} & 25 . & 20 . & \text { fifth } & 140 . & 175 . \\\hline \mathrm{D} & 20 . & 35 . & \text { second } & 30 . & 70 . \\\hline \mathrm{E} & 15 . & 10 . & \text { sixth } & 155 . & 185 . \\\hline \text { F } & 10 . & 25 . & \text { first } & 10 . & 35 . \\\hline \text { Makespan } & & && & 185 . \\\hline\end{array} A BCDE F Makespan FR 50.35.25.20.15.10. OS 30.55.20.35.10.25. Order fourth third fifth second sixth first Done 1 115.65.140.30.155.10. Done 2 (flow time) 155.125.175.70.185.35.185.

Sequence: F, D, B, A, C, E \text { Sequence: F, D, B, A, C, E } Sequence: F, D, B, A, C, E (c) The schedule appears in the chart below. (d) Job A is being processed at FR (Machine 1), while Job B is being processed at OS (e) Total flow time for the schedule is 185.

(Machine 2)

(Machine 2)

Learning Objectives

- Apply Johnson's rule to find the optimal job sequence for minimizing makespan in a two-machine system.

- Review the capability of different scheduling systems considering criteria such as average flow time, work-in-process, lateness, and makespan.

Related questions

The President of a Consulting Firm Wants to Minimize the ...

The Following Jobs Are Waiting to Be Processed at Your ...

At Morgan's Transformer Rebuilding, Five Jobs Are Ready Now for ...

A Firm That Specializes in Desktop Publishing for Local Charities ...

The Operations Manager of a Body and Paint Shop Has ...